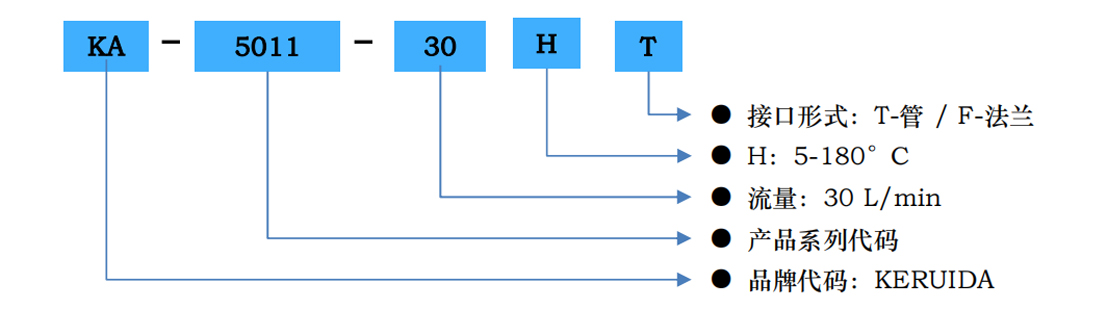

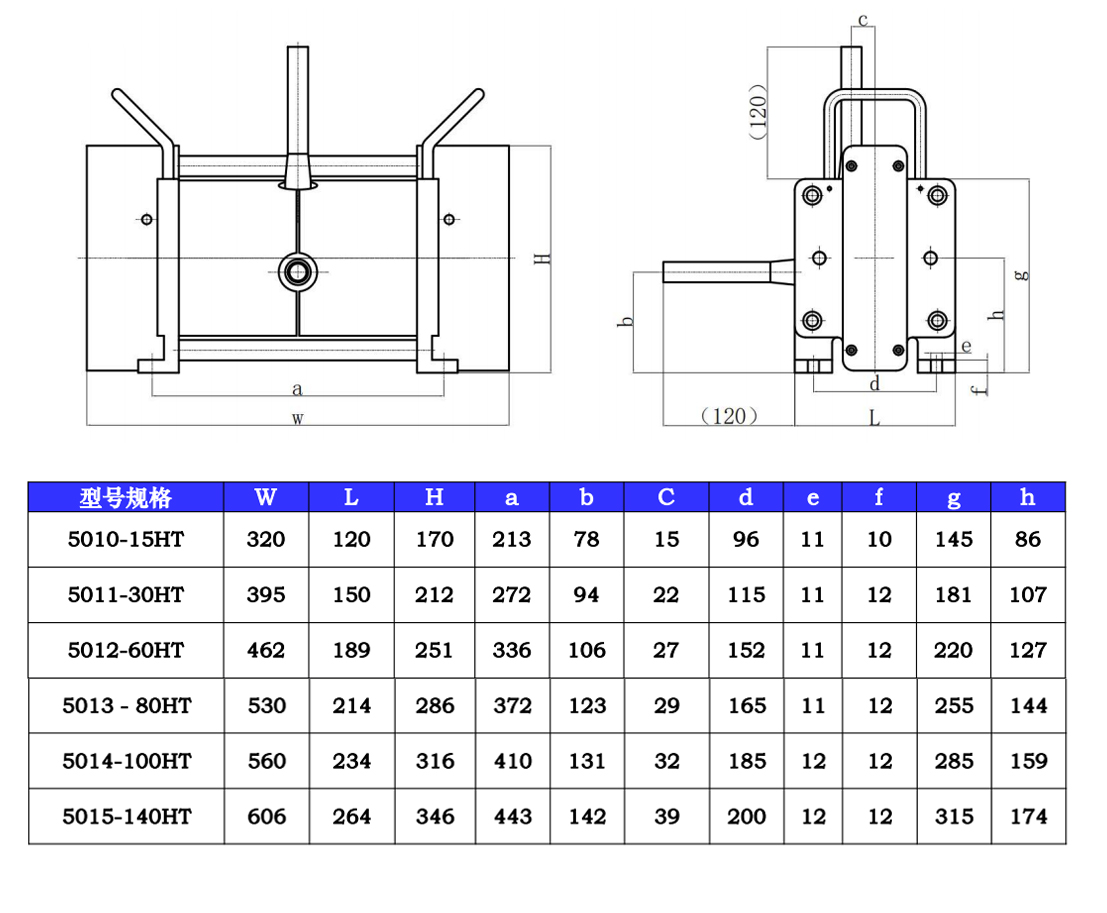

Keruida's latest pneumatic air sac pump is developed on the basis of accumulated years of experience. By increasing the stroke of the pump, the product size is optimized, the manufacturing cost of the product is reduced, the operation is convenient, and the liquid temperature range is large. The core components of the pump are made of high-purity fluorine material, which realizes high-pressure discharge and extends the service life. Minimize pollution, complete manufacturing, assembly and testing in a dust-free environment, and be competent for a variety of difficult working conditions such as: from cleaning liquid circulation, CMP grinding liquid circulation, chemical liquid distribution and supply, etc.

Keruida's pneumatic air sac pump is a cost-effective pneumatic pump with high temperature resistance, corrosion resistance, long service life, and is particularly suitable for the circulation and transportation of small flow and high-purity chemicals. The pump transmits a signal to change the direction of the solenoid valve through the built-in proximity switch. After connecting with various controllers, the discharge volume of the pump can be easily controlled or managed.

For semiconductor and liquid crystal processes with extremely high requirements for cleanliness, no particles and pollution should be generated or mixed with liquid medicine during delivery. The air sac pump is specially designed for the manufacturing process of semiconductor, solar energy, LED, panel industry, optoelectronics industry, and electronics industry. All parts in contact with the liquid are made of high purity.It is made of fluorine resin material, and the external parts of the device are also coated with fluorine resin coating. There is no exposure of metal parts, which greatly meets the requirements of corrosion resistance. Its main characteristics include:

1. The inside of the pump body is an integrated structure, which is completely sealed to reduce the risk of leakage.;

2. Compact structure, high stroke rate design, reduced weight and low cost;

3. It is designed with strong temperature and chemical resistance. All overcurrent parts are made of non-polluting high-purity fluorine materials.;

4. The liquid temperature range is large, and the liquid can be transported in the range of 5~180℃, without the need to use cooling water in the thermal cycle.;

5. The high-density air sac is processed from extremely high-purity and high-density PTFE, which has excellent ductility and fatigue resistance.;

6. The drive system has a built-in proximity sensor, which can effectively control the action of the external air source solenoid valve. Switch;

7. It can be tested without load, will not damage the parts of the pump body, and is equipped with a leakage sensor. There is an alarm to remind when the internal fluid leaks.;

8. It can be started at low pressure to reduce air consumption and extend service life. Adjusting the air pressure can control the discharge of the pump.;

9. Under normal use, it can operate safely and reliably during the warranty period of up to two years.;

Home

Home Products

Products Telephone

Telephone Message

Message