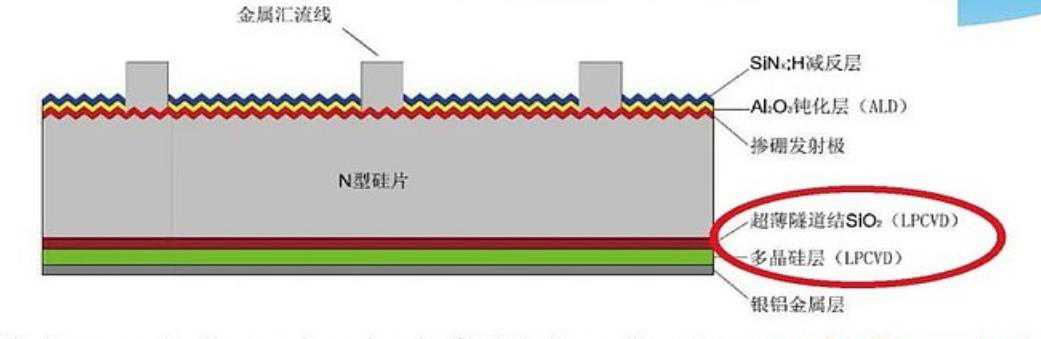

TOPCon(TunnelOxidePassivatedContact)——Oxide layer passivates contacts. The front side is not essentially different from conventional N-type solar cells or N-PERT solar cells. The core technology of the battery is the back passivation contact. The back of the battery is composed of a layer of ultra-thin silicon oxide (1~2nm) and a layer of phosphorus-doped microcrystalline amorphous mixed Si film, which together form a passivating contact structure. The passivation performance is activated through the annealing process. During the annealing process, the crystallinity of the Si film changes, transforming from a microcrystalline amorphous mixed phase to polycrystalline. Annealed at an annealing temperature of 850°C, iVoc>710mV, J0 at 9-13fA/cm2, showing excellent passivation performance of the passivated contact structure. This structure can block the recombination of minority carrier holes and increase the open circuit voltage and short circuit current of the battery. The ultra-thin oxide layer can tunnel multi-carrier electrons into the polysilicon layer while blocking the recombination of minority carrier holes. The good passivation effect of ultra-thin silicon oxide and heavily doped silicon films causes the surface energy band of the silicon wafer to bend, thereby forming field passivation. As a result, the probability of electron tunneling is greatly increased, the contact resistance is reduced, and the open circuit voltage and short circuit current of the battery are increased, thereby improving the battery conversion efficiency.

This structure can block the recombination of minority carrier holes and increase the open circuit voltage and short circuit current of the battery. The ultra-thin oxide layer can tunnel multi-carrier electrons into the polysilicon layer while blocking the recombination of minority carrier holes. The good passivation effect of ultra-thin silicon oxide and heavily doped silicon films causes the surface energy band of the silicon wafer to bend, thereby forming field passivation. As a result, the probability of electron tunneling is greatly increased, the contact resistance is reduced, and the open circuit voltage and short circuit current of the battery are increased, thereby improving the battery conversion efficiency.

Figure 2: TOPCon battery structure

Route 1: Intrinsic + phosphorus expansion: LPCVD prepares polysilicon film combined with traditional full diffusion process. It is relatively mature, short in time, and has high production efficiency. It is the mainstream route chosen by TOPCon manufacturers at present; however, there is the problem of excessive plating.

Route 2: In-situ doping: PECVD prepares polysilicon film and in-situ doping process. The deposition speed is fast and the deposition temperature is low. PECVD can also be used to prepare polysilicon layers to simplify the process.

Route 3: Ion implantation: LPCVD preparation of polysilicon film combined with boron expansion and ion implantation of phosphorus. Ion implantation technology is a single-sided process, and doping ions does not require winding. However, the boron expansion process is more difficult, time-consuming, and requires higher equipment than the phosphorus expansion process.

Chart 3: TOPCon’s main technical routes

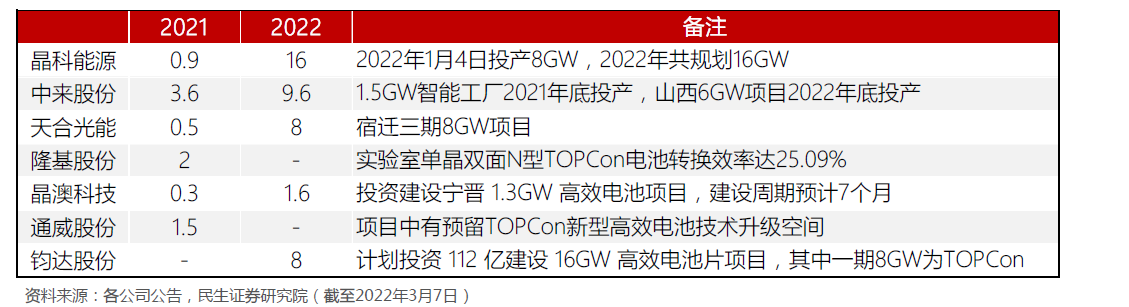

Various manufacturers are accelerating TOPCon production capacity planning and advancing the industrialization process. In the past two years, domestic companies have basically reserved space for TOPCon transformation in PERC's new production lines for subsequent upgrades. The PERC production capacity of many first-tier manufacturers has gradually stopped, and current production expansion plans have also turned to the construction of N-type technology production lines. Entering the second quarter, many manufacturers, including Jinko, have begun to release TOPCon production capacity and are expected to enjoy technology premiums.

Major companies: Longi, Jolywood, Jinko, Trina Solar, Risen Energy, etc. Most of them are vertically integrated companies. Due to the large existing production capacity of PERC batteries, the newly added PERC production capacity in 2019 basically reserves the TOPCon interface for subsequent upgrades.

Conversion efficiency: Jolywood is one of the first companies to deploy TOPCon. Currently, the average conversion efficiency of its TOPCon battery mass production batches is 24.2%, and some products reach 24.5%. The highest laboratory conversion efficiency currently announced by TOPCon is 25.4%, which will be announced in mid-2021. JinkoSolar is the first company to achieve GW-level shipments at TOPCon. It is expected that JinkoSolar's single-quarter TOPCon shipments in the second quarter are expected to exceed 1GW.

Capacity planning: Referring to the statistics of PVInfoLink and TrendForce New Energy, the industry-wide TOPCon production capacity is expected to exceed 40GW by the end of 2022, and is expected to reach approximately 80GW by the end of 2023.

Chart 4: TOPCon production expansion plans of each battery factory (incomplete statistics) (Unit: GW)

Content source: Minsheng Securities

Home

Home Products

Products Telephone

Telephone Message

Message