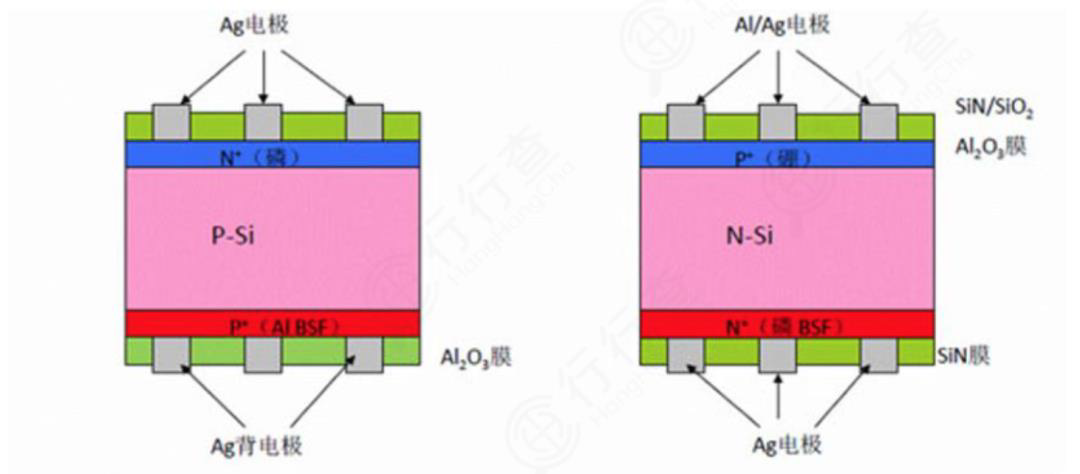

Crystalline silicon battery technology uses silicon wafers as the substrate, and is divided into P-type batteries and N-type batteries based on the differences in silicon wafers. There is no essential difference in the power generation principles of the two batteries. They both rely on the PN junction for separation of photogenerated carriers. A solar cell in which phosphorus is diffused on a P-type semiconductor material to form an n+/p-type structure is a P-type cell; a solar cell in which boron is injected into an N-type semiconductor material to form a p+/n-type structure is an N-type cell. piece.

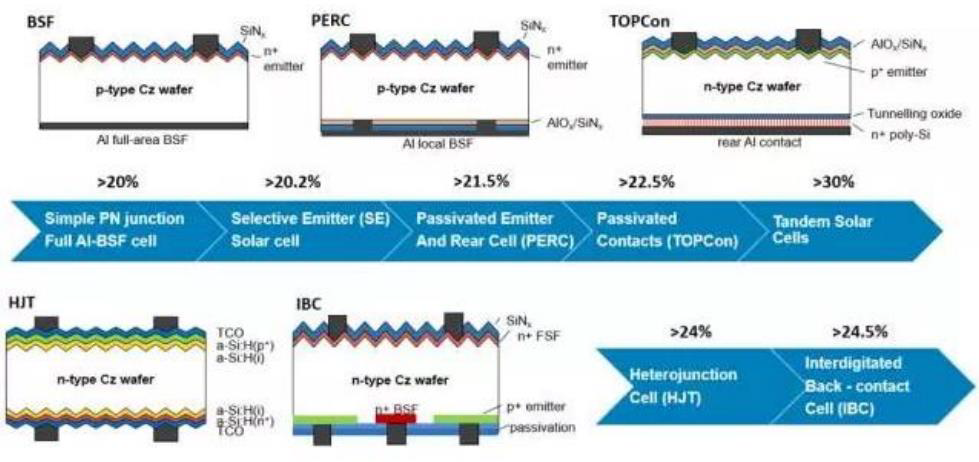

Chart 1: Photovoltaic cell technology iteration path

Figure 2: Schematic structural diagram of P-type battery (left) and N-type battery (right)

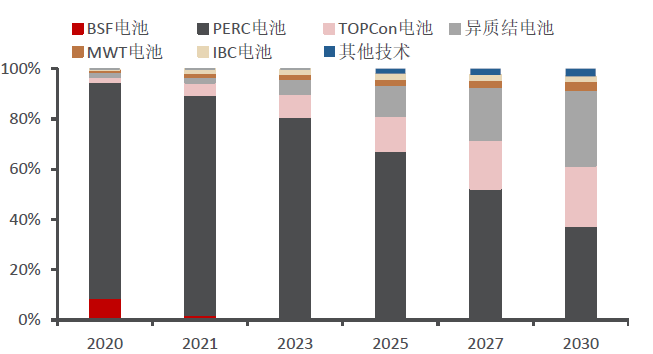

The production process of P-type batteries is relatively simple and the cost is low, mainly BSF batteries and PERC batteries. Before 2015, BSF batteries accounted for 90% of the market; after 2016, PERC batteries took over and by 2020, PERC batteries accounted for more than 85% of the global market.

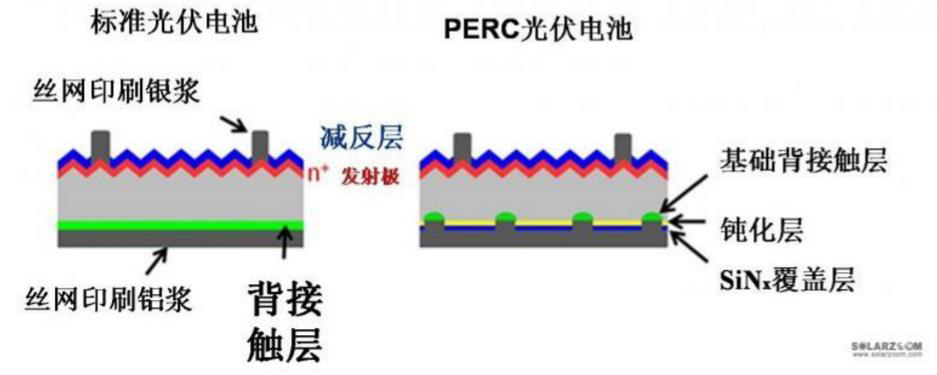

PERC (Passivated Emitter Rear Cell) - emitter and back passivated battery technology. The difference from conventional batteries is the back. PERC cells use a passivation film to passivate the back, replacing the traditional all-aluminum back field to enhance the light emission on the silicon base. The internal back reflection reduces the recombination rate on the back, thereby increasing the battery efficiency by 0.5%-1%.

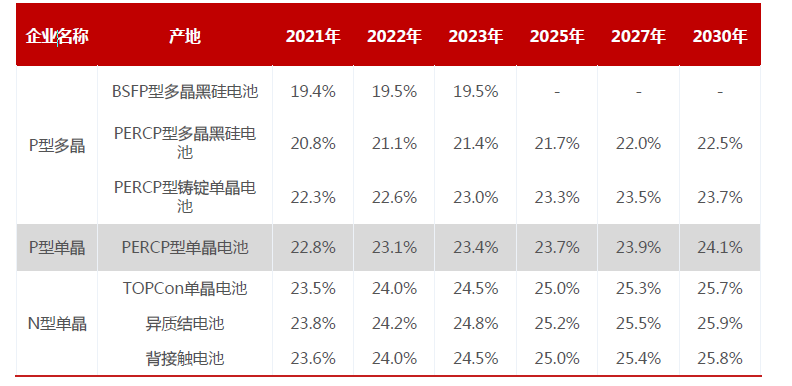

In 2020, the average conversion efficiency of large-scale production of single/polycrystalline cells reached 22.7% and 19.4% respectively. P-type monocrystalline cells have adopted PERC technology, and the average conversion efficiency has increased by 0.5 percentage points year-on-year.

Chart 3: Schematic diagram of PERC battery and conventional battery principles

Figure 4: Trends in market share of various battery technologies from 2020 to 2030

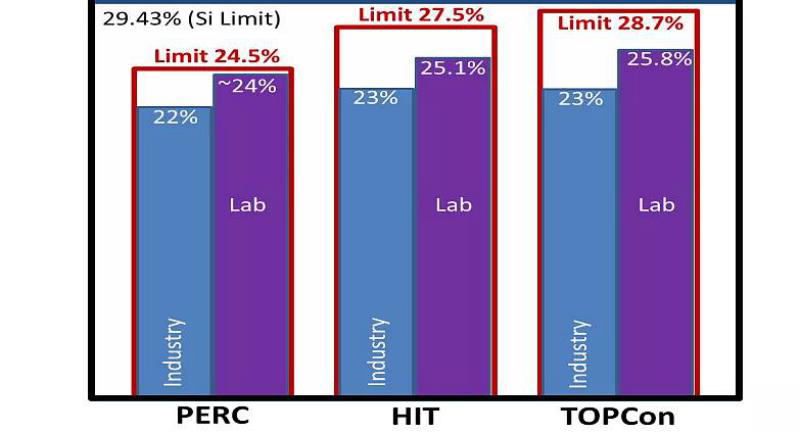

Since the theoretical conversion efficiency limit of P-type monocrystalline silicon PERC cells is 24.5%, it is difficult to significantly improve the efficiency of P-type PERC monocrystalline cells; and it has not been able to completely solve the problems caused by cells based on P-type silicon wafers. The phenomenon of light decay and these factors make it difficult for P-type silicon cells to develop further.

Compared with traditional P-type monocrystalline cells and P-type polycrystalline cells, N-type cells have high conversion efficiency, high bifacial ratio, low temperature coefficient, no light attenuation, good low-light effect, and longer carrier life, etc. advantage.

Chart 5: Forecast of conversion efficiency of various battery technologies from 2020 to 2030

Chart 6: Theoretical ultimate efficiency of silicon-based batteries with different technical routes

Content source: Minsheng Securities

Home

Home Products

Products Telephone

Telephone Message

Message